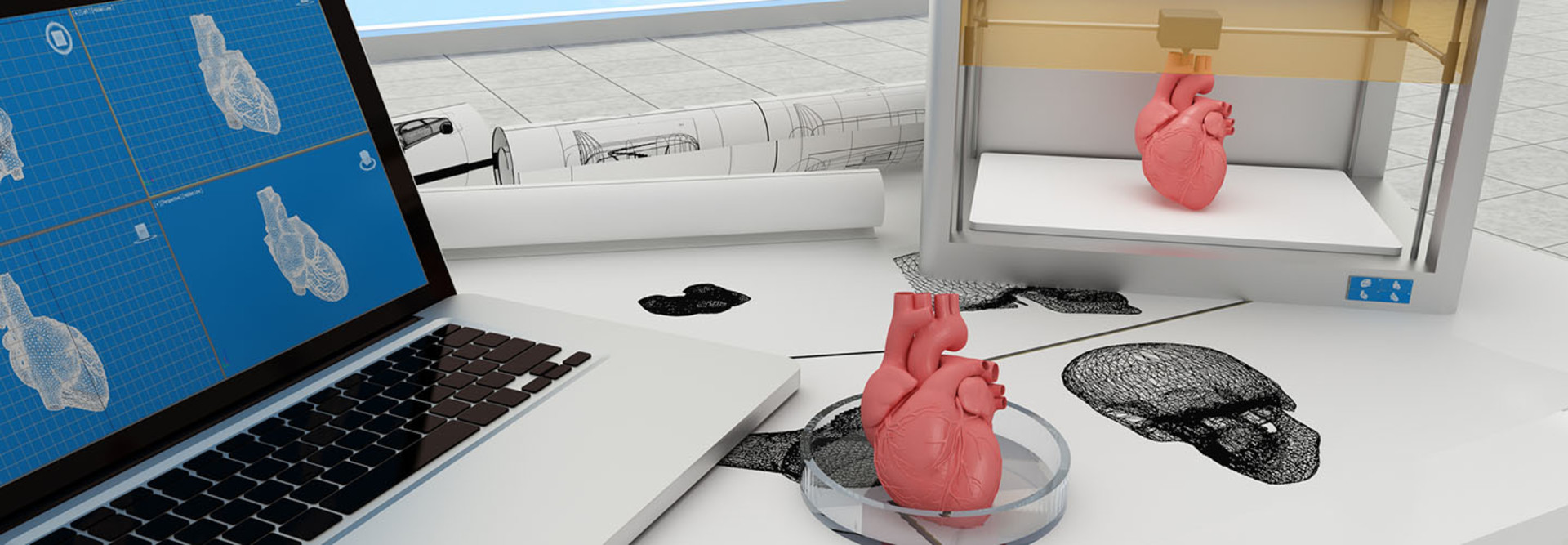

Is 3D Printing in Healthcare a Medical Revolution?

For a technology that hasn’t yet entered onto the grounds of most hospitals or healthcare organizations, 3D medical printing is well on its way to significantly influencing the industry.

Despite a lack of widespread adoption, the tool already is thriving in the healthcare scene, facilitating difficult surgeries such as the recent separation of twins with conjoined hearts through the use of 3D-printed models and virtual reality — a surgery for which there were previously no known survivors.

But, “it’s still innovative hospitals that are making these models that are helping them with difficult surgeries,” says Alan Louie, the research director for IDC’s Health Insights Life Sciences Practice. While most hospitals currently don’t use 3D printers except for small plastics, the tool is setting itself up to revolutionize areas of medicine such as prostheses and implants in the near term, Louie notes.

Driven by these types of applications that affect patients and providers, as well as by heavy research and investment in 3D printing use cases, adoption of the technology will likely continue to rise. In fact, the healthcare sector will largely contribute to pushing global spending on 3D printing from $13 billion in 2016 to a predicted $28.9 billion in 2020, according to a recent IDC report.

“There is a lot of investment in 3D printing at the moment because there are some very clear ways that the technology can be used to improve existing processes,” says Louie. “There are areas where you can determine that using a 3D-printed replacement for the current methodology can actually save money, improve healing, reduce pain, improve patient acceptance — all positive driving factors that are helping the industry move forward.”

So where is 3D printing in healthcare taking off and what might the future hold?

SIGN UP: Get more news from the HealthTech newsletter in your inbox every two weeks

3D Printing in Healthcare Means Comfortable, Cost-Effective Prostheses and Implants

3D printing in healthcare is already proving its worth in the prostheses and implants space, driven in part by a new collaboration between the Department of Veterans Affairs and Stratasys, the 3D printing and additive manufacturing company that produces Makerbot 3D printers.

Per the agreement, Stratasys is equipping five VA hospitals in the U.S. with 3D printers, materials and training, with the aim to encourage development of “custom orthotics, prostheses, and anatomical models for personalized healthcare,” according to a press release. By enhancing access to 3D medical printing, the network is designed to have a positive impact on doctor preparedness, surgical collaboration and, in turn, patient care and more streamlined costs, HealthTech reports.

“The overarching vision for 3D printing is universal availability at all 168 VA hospitals across the country — accelerating development of personalized healthcare, tools and technologies for veterans and their families,” Beth Ripley, a staff radiologist at the Seattle division of the VA Puget Sound Healthcare System, said in a blog post.

Not only can 3D printing in medicine help to build custom tools and equipment for patients that require prostheses, it can make the actual prosthetic device much more comfortable and effective.

“By using imaging directly from the patient, you can design specifically a replacement — like a hip or skull implant or another required external replacement for something missing in the body — to fit much better than an off-the-shelf product. As a result, you will have a much faster surgical time, much faster healing time and less pain. It works out, in most cases, to the advantage of the patient,” says Louie.

Moreover, 3D bone and organ printing can turn out to be significantly more cost effective.

“In the past, constructing a prosthetic to replace a missing hand could cost tens of thousands of dollars or more to the patients and healthcare system. With the advent of 3D printing, you can now print a prosthesis for a few hundred dollars,” says Louie.

This has a particularly poignant application for children with prostheses, who outgrow the prosthetic devices every few months.

“With traditional methodologies, families couldn’t afford to spend the tens of thousands of dollars every few months to get a larger prosthetic. This makes it much more practical,” says Louie.

3D Bioprinting Begins to Pick Up Steam

While 3D printing has the chance to transform the healthcare industry, the concept of bioprinting, or printing laboratory-grown cells in order to form living structures, could have an even more profound impact.

“The approach could revolutionize regenerative medicine, enabling the production of complex tissues and cartilage that would potentially support, repair or augment diseased and damaged areas of the body,” Science Daily reports.

For the moment, successful 3D bioprinting in the mainstream is still a ways off, according to Louie, who notes that while some researchers have managed to print organic material, structural integrity with 3D-printed cells has proven to be a challenge.

However, research into successfully bioprinting reproducible organic materials recently made some headway. A team of scientists from Oxford and Bristol universities this week published a study in Scientific Reports that demonstrates a low-cost method of bioprinting a “range of human and animal cells” into “high-resolution tissue constructs,” according to Science Daily.

The site reports: “To be useful, artificial tissues need to be able to mimic the behaviours and functions of the human body. The method enables the fabrication of patterned cellular constructs, which, once fully grown, mimic or potentially enhance natural tissues.”

The study concluded in 2016. Since then, the scientists have taken steps to commercialize the technology with the hope that, with further development, it can replace clinical animal testing.

The Future of 3D Medical Printing

Despite the headway that 3D printing has made in medicine, challenges remain.

“What’s at the crux of holding the spread of this technology back is the development of materials that can be deposited using 3D printing,” says Louie.

But with intense research and funding flowing into the space, it is likely that innovative products will come onto the scene with time.

“In particular, where we look at what’s going on in the implant space, the ability to infuse the 3D-printed medical device with drugs or other biological factors that may either reduce rejection or improve healing are likely to be the next innovations down the road,” says Louie.

Moreover, 3D-printed pills could potentially revolutionize the pharmaceutical sector by offering custom doses directly from the pharmacist, while 3D-printed skin could heal burns or wounds. And there’s likely use cases we haven’t even thought of yet.

“The use of 3D printing is clearly in its infancy,” says Louie. “Healthcare has some clearly defined unmet needs and areas of improvement, but I think the uses will be much broader.”