FDA Framework Seeks to Outline the Future of 3D Printing in Healthcare

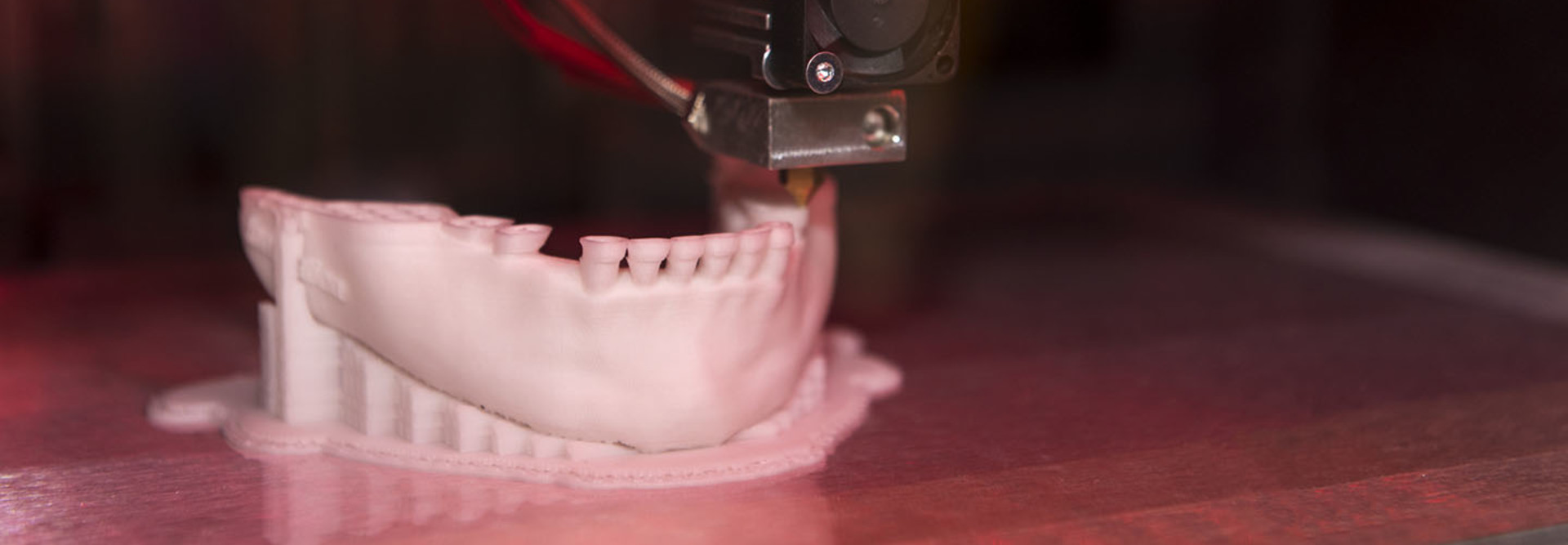

As innovative providers and clinicians begin using 3D printing to create custom prosthetics, implants and medical devices, it can feel like the additive manufacturing health revolution is already here. But with techniques such as bioprinting, which pertains to biological, cellular and tissue-based products, and custom-printed pharmaceuticals still on the horizon alongside hundreds of other undiscovered uses, the health industry is only just dipping its toes in the waters of what 3D printing can achieve.

To help frame the future of 3D printing in the healthcare industry, the Food and Drug Administration has released detailed guidance for 3D printer manufacturers.

“Patients have already benefitted from 3D-printed medical products through access to personalized devices and innovative drugs that have led to significant health improvements. But the FDA is now preparing for a significant wave of new technologies that are nearly certain to transform medical practice,” FDA Commissioner Scott Gottlieb says in a statement, adding that the FDA is working to draw out a “more comprehensive regulatory pathway” that will keep up with the pace of 3D printing advancements and encourage safe and effective innovation.

SIGN UP: Get more news from the HealthTech newsletter in your inbox every two weeks!

FDA Offers 3D Printing Guidance Ahead of Regulations

To create the framework, the agency reviewed more than 100 3D-printed products, including custom-printed prosthetics, which are quickly making prosthetics more comfortable and affordable for patients. The FDA also looked into the first 3D-printed pharmaceutical, a seizure drug that has a “more porous matrix than the drug manufactured in the traditional way,” allowing the medication to dissolve more rapidly. It enters the bloodstream more quickly and, as a result, works faster for the patient.

Going forward, the FDA says there is also the potential to treat burn patients with their own skin cells, 3D printed directly onto their wounds, as well as the potential to print and replace organs.

As these techniques edge closer to reality, the FDA’s new guidance looks to help manufacturers move forward with safe and effective ways to design and test the quality of new systems.

“Overall, it will help manufacturers bring their innovations to market more efficiently by providing a transparent process for future submissions and making sure our regulatory approach is properly tailored to the unique opportunities and challenges posed by this promising new technology,” Gottlieb says.

He points out, however, that the new guidance is only among the first steps in standardizing the approach to 3D printing in the healthcare field, and that as new technologies and practices emerge, so will more formal regulations.

“In order to help ensure the safety and effectiveness of these products, we’re working to establish a regulatory framework for how we plan to apply existing laws and regulations that govern device manufacturing to nontraditional manufacturers like medical facilities and academic institutions that create 3D-printed personalized devices for specific patients they are treating,” says Gottlieb, adding that developing a “transparent policy on 3D printing” is an important next step for the agency.

As it develops these regulations, the FDA also plans to explore the role of “nontraditional manufacturing facilities like a hospital operating room or university laboratory,” as well as look into bioprinting.

“3D printing is certain to alter the daily practice of medicine where patients will be treated with medical products manufactured specifically for them,” Gottlieb says. “The FDA has an important mission to help advance these efforts while also protecting patients who depend on medical products to be safe and effective.”